How To Inflate A Tubeless Tire

Flat tire? It’s happened to all of us. The frustration of a sudden puncture can be quickly overcome if you know how to put air in a tubeless tire. This guide will walk you through the process, explaining the tools you’ll need, the steps involved, and troubleshooting common problems. You’ll learn to confidently handle tire inflation, saving yourself time, money, and a whole lot of frustration in the long run. By the end, you’ll be a tubeless tire inflation expert!

Understanding Tubeless Tire Inflation

This section explains the fundamental differences between tubeless and tubed tires and highlights the unique aspects of inflating tubeless tires. We’ll cover the crucial role of the tire bead and sealant, and the importance of proper pressure. You’ll learn why using the right technique is essential for a successful and safe inflation.

The Tire Bead and its Seal

- The tire bead is the reinforced edge of the tire that sits against the rim of the wheel. It’s designed to create an airtight seal when properly seated. A properly seated bead is crucial for maintaining air pressure and preventing leaks. Failure to seat the bead correctly can lead to repeated deflation and frustration.

- Tubeless tires rely on a tight seal between the tire bead and the rim. This seal prevents air from escaping. The design of both the rim and the tire bead is critical for a successful seal.

- Improper seating can lead to air leakage, requiring reseating efforts or sealant additions. A poorly seated bead is the most common cause of failure to inflate a tubeless tire.

Sealant’s Role in Tubeless Tires

- Tubeless tire sealant is a liquid added inside the tire that seals small punctures. This sealant acts as a preventative measure and as a repair for minor damage that may occur while riding.

- The sealant creates an immediate seal preventing further air loss in small punctures. While sealant isn’t a complete replacement for a puncture repair, it is a valuable time saver and can help you make it home after a puncture.

- Different sealants have varying viscosities and effectiveness. Choose a sealant suitable for your riding conditions and tire type.

Air Pressure and its Importance

- Maintaining the correct tire pressure is crucial for optimal performance, comfort, and safety. Underinflation reduces traction and increases the risk of pinch flats, while overinflation can lead to discomfort and premature tire wear.

- The recommended tire pressure is usually printed on the sidewall of the tire. This pressure should be checked regularly and adjusted as needed.

- Using a reliable pressure gauge is essential to ensure accurate inflation. Inexpensive gauges can sometimes provide inaccurate readings leading to under or over inflation.

Essential Tools for Tubeless Tire Inflation

This section details the necessary equipment for successfully inflating a tubeless tire. We’ll discuss the importance of each tool and offer suggestions for choosing the right ones. Ensuring you have the correct tools beforehand greatly reduces the difficulty and potential frustration of the process.

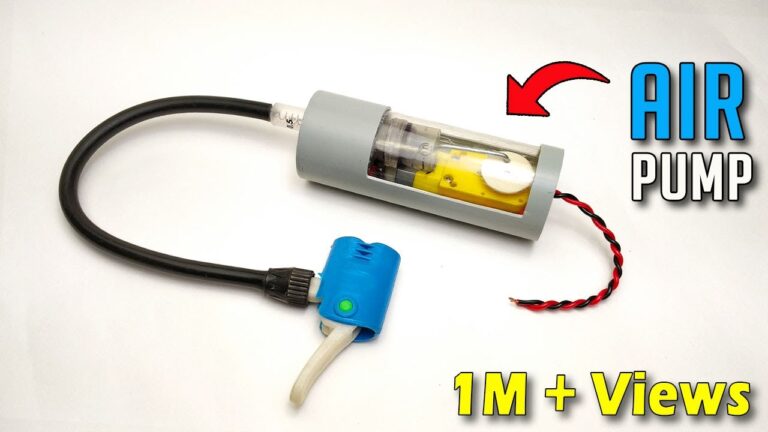

High-Volume Air Pump

- A high-volume air pump is necessary to quickly seat the tire bead. A standard bicycle pump often lacks the necessary airflow to rapidly reach the required pressure to seat the bead. A high-volume pump will quickly inflate the tire to a pressure exceeding the seating pressure of the bead.

- Consider a pump with a pressure gauge to monitor pressure accurately. This gauge helps to ensure the tire is properly inflated.

- Look for pumps with different nozzle adapters for compatibility with various valve types (Presta and Schrader).

Tire Levers (Optional)

- Tire levers can help in seating a stubborn tire bead. These levers provide leverage to help get the bead over the rim in difficult situations.

- Plastic levers reduce the risk of damaging the rim. Metal levers can scratch or damage the rim.

- Using tire levers requires care and technique to avoid damaging the rim or tire. Using too much force can result in damage.

Air Pressure Gauge

- An accurate pressure gauge is essential for checking and maintaining the correct tire pressure. Inaccurate pressure can negatively impact ride quality and tire longevity.

- Choose a gauge that’s reliable and easy to read. Digital gauges often offer greater precision compared to analog options.

- Regularly calibrate your pressure gauge to ensure accuracy. A simple gauge calibration can prevent numerous problems related to tire pressure.

Step-by-Step Guide: How to Put Air in a Tubeless Tire

This section provides a clear, step-by-step guide to inflating a tubeless tire. We’ll cover each step in detail, emphasizing safety and efficiency. Following these steps will maximize your chances of success and reduce the likelihood of errors.

Preparing the Tire and Rim

- Ensure the tire is properly seated on the rim. Inspect the tire and rim for any visible damage or obstructions. Any debris in the bead seat can prevent the tire from sealing properly.

- Check for any obvious punctures or damage before attempting inflation. Large punctures may require more extensive repairs before the tire can be successfully inflated.

- Make sure you have your high-volume pump, pressure gauge, and tire levers (if needed) ready.

Seating the Tire Bead

- Start by adding some air to the tire. You might need to use a floor pump or compressor that will quickly get the bead to pop onto the rim.

- Hold the valve stem to secure it from blowing off from high pressure. Make sure the bead is fully seated across the entire rim before adding further air.

- If the bead is proving difficult to seat, use tire levers to assist; take care not to damage the rim or the tire.

Inflating to the Correct Pressure

- Once the bead is seated, continue inflating the tire to the recommended pressure printed on the sidewall.

- Use your pressure gauge to monitor the pressure accurately. Regularly check your pressure gauge for accuracy.

- If the tire continues to lose pressure even after the bead is seated, check for leaks and potentially add additional sealant.

Inspecting for Leaks

- After inflating the tire, inspect it carefully for any visible leaks. Listen for any hissing sounds indicating air escaping.

- Check the valve stem for leaks; apply soapy water to any suspect areas to identify any subtle escapes.

- If a leak is found, try to locate the source; a small puncture may seal itself with sealant, but a larger one may require repair.

Troubleshooting Common Problems

This section addresses common challenges encountered during tubeless tire inflation, providing solutions and preventative measures. Understanding these issues will help you confidently resolve problems and avoid future difficulties.

The Tire Bead Won’t Seat

- Check for any obstructions in the tire bead seat. Carefully remove any dirt, debris, or sealant that might be preventing the bead from seating properly.

- Use tire levers carefully to help seat the bead; however, use extreme caution as to not damage the rim or tire.

- If the problem persists, consider using a higher-volume air source or a compressor. The air pressure required can be surprisingly high to get the tire bead to seat.

Slow Leak After Inflation

- Check the valve stem carefully. A faulty valve stem can cause slow leaks and could need replacing.

- Inspect the tire thoroughly for any punctures. Use soapy water to help pinpoint potential leaks.

- If the leak is very slow, additional sealant might be necessary. Consider adding more sealant to help seal small punctures or tears that might be present.

The Tire Bursts During Inflation

- This is usually caused by a previously damaged tire or a flaw in the rim. Inspect the tire and rim very carefully for any preexisting damage before re-attempting inflation.

- Make sure the inflation pressure is not exceeding the recommended limit marked on the tire sidewall. Overinflation can easily cause a tire to burst.

- Avoid using excessive force during inflation. Do not inflate the tire beyond the recommended pressure.

FAQ

What is the best way to inflate a tubeless tire?

The best way is to use a high-volume air pump and a pressure gauge. Ensure the tire bead is properly seated before inflating. Gradually increase the pressure until reaching the recommended level printed on the sidewall. Monitor for leaks using soapy water and address any issues promptly.

How much air pressure should I put in my tubeless tire?

The recommended air pressure is usually printed on the sidewall of your tire. Consult your tire’s specifications for the correct amount. Pressure depends on the size of the tire and the rider’s weight.

What happens if I put too much air in a tubeless tire?

Overinflating your tire can cause discomfort, reduced traction, and premature wear. In extreme cases, it can even lead to a tire blowout.

What if my tubeless tire keeps losing air?

Check the valve stem, inspect the tire for punctures, and add more sealant if needed. A slow leak may indicate a very small puncture, which the sealant can seal.

Can I use a regular bike pump to inflate a tubeless tire?

While possible for some tires, a regular bike pump may not generate enough volume to fully seat the tire bead. A high-volume pump is recommended for most tubeless tire installations.

What should I do if I can’t seat the tire bead?

Try using tire levers to assist in seating the bead, ensure the rim is clean and free from debris, and use a high-volume air pump to quickly increase pressure. If you continue to have problems, seek assistance from a bicycle mechanic.

What kind of sealant is best for tubeless tires?

Different sealants offer varying performance based on viscosity and sealing capabilities. Consider the intended use (road, mountain, gravel) when selecting sealant for your tire.

Final Thoughts

Mastering the art of how to put air in a tubeless tire is a valuable skill for any cyclist. By understanding the process, gathering the right tools, and following these steps, you can confidently handle flat tires and keep riding. Remember to always check your tire pressure regularly and keep your sealant topped off for maximum performance and safety. Now go forth and conquer those flat tires!